Although no one is certain of exactly when and where cotton cloth originated, archeologists do know that people were weaving cotton fiber into fabric as long as 4,000 years ago in India and Central and South America. By 1500 A.D, the plant was cultivated throughout the warmer regions of the Americas, Eurasia and Africa.

Until the late 18th century, cotton was grown, harvested, ginned, spun and woven by hand, with only the wealthy able to afford to buy it. Two significant inventions change this: the water-powered spinning machine and the cotton gin. The cotton gin, a hand-cranked device that strips the plant’s fibers from its seeds, enabled a worker to clean not one but 50 pounds a day. After these two inventions, the U.S. became the world’s foremost supplier of cotton fiber.

India led the manufacture of cotton cloth prior to the advent of the Industrial Age, when England became the market leader. Eventually, Indian mills purchased new machinery, regaining control of the marketplace. But as volume and profits grew, the workers suffered. Gandhi brought world attention to the plight of Indian textile workers in 1918 when he staged a fast that ultimately led to the independence of India.

For nearly 4,000 years, cotton was grown organically. But with the development of pesticides and chemical fertilizers during WWII, this changed. By the late 1950s, only 10 years after their introduction, cotton, like so many other agricultural products, was grown and harvested with the use of pesticides, the most famous of which was DDT.

Despite early warning signs of the damage these chemicals cause, today insecticides, herbicides, fungicides and chemical fertilizers are applied to cotton throughout its growing cycle.

We find it ironic that the term “conventionally grown” refers to this type of growing and harvesting, which has only been in practice for 50 years, versus the preceding 4,000 years of organic growing and harvesting.

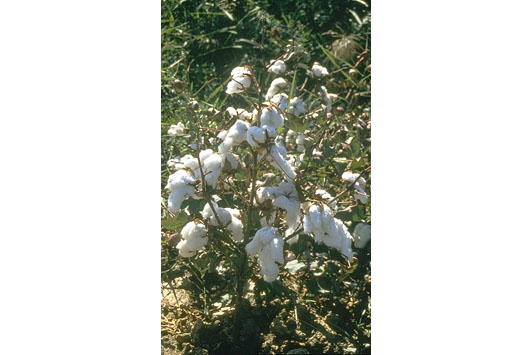

It is distressing to learn that a plant so pure and beautiful, and basic to daily life now requires:

- 25% of all insecticides used are used on cotton

- 200 chemicals might be applied to a single plant in one season in the U.S. This translates to 1/3 of a pound of chemicals per pound of cotton fiber

If all cotton were grown organically, the use of insecticides worldwide would be reduced by 25%. We, at Coyuchi, are working towards this end.

Coyuchi uses only 100% certified organic cotton in our bedding and has been recognized for our efforts, receiving the United Nations Second Annual Fashion Industry Award for Environmental Excellence.

Every fiber of cotton we spin is produced in accordance with the standards of the International Federation of Organic Agricultural Movements (IFOAM). To be certified as organic cotton, the following requirements have to be met:

- Seeds must be non-genetically engineered.

- Insects should be controlled by methods that stimulate what occurs in the natural environment where good bugs eat bad bugs.

- Emphasis must be placed on keeping plants healthy. Health plants are more resistant to infestation.

- Chemical fertilizers or inputs, such as herbicides or other pesticides, cannot be used.

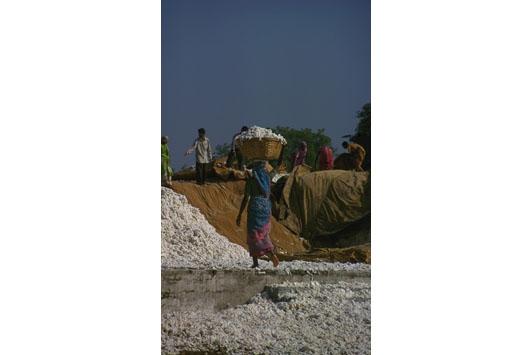

- Fields are weeded by hand.

• Farming communities are healthy.

Growing cotton organically reduces costs and increases revenues for the farmers who grow it. It also improves soil fertility and porosity, so less water is required. And finally, provides an agricultural ecosystem that produces healthy food.

Organic cotton is grown rotationally and alongside maize, sesame, sorghum and chilies, and inter-cropped with nitrogen-fixing plans such as lentils and chickpeas. Some of these plants serve as barriers that repel pests. Others, such as maize and sorghum, attract beneficial insets. Soil fertility is managed with the application of manure, compost and earthworm castings, in addition to rotating the crops, supplementing the rotation with oil cakes, and using other biodynamic preparations.

In addition to exclusively using certified organically grown cotton, we openly disclose our certifiers because we believe it is the right way to do business.

The cotton is certified by Control Union Certifiers and EcoCert International according to the European regulation standards (EEC 2092/91).

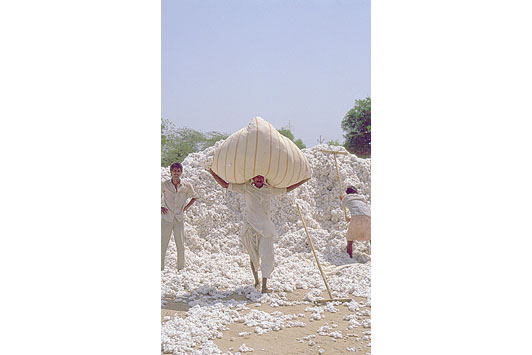

First, we gin the cotton which is the process of removing the seeds from the plant. The seeds account for 2/3 of the weight of raw cotton. 354,000 pounds of cotton seed result in 118,000 of lint.

Net, the lint is spun. Approximately 30 percent of the lint is composed of short fibers called noile. The noile is removed during the combing process and used to make organic cotton batting and for stuffing mattresses.

From our 118,000 pounds of combed cotton, we make approximately 83,000 pounds of yarn. From this yarn, we are able to make 8,000 sheet sets, 4,000 towel sets, 1,200 jacquard blankets, 1,000 robes and a small amount of knit fabric for baby clothing.

All our fabrics are processed with an amylase enzyme removes the wheat starch sizing. Fabric is scoured with biodegradable soap and caustic soda.? White, bleached fabrics are whitened using hydrogen peroxide.

Dyed fabrics are colored with low-impact fiber reactive dyes. These require less water, heat and dye material than other commonly-used cotton dyes. There is less residual color left in the rinse water due to the high bonding coefficient between the dye material and the cotton fiber.

Sanforizing, pre-shrinking, is a mechanical process that uses steam and rubber pads and rollers. It involves no chemicals.

- The cotton we produce in India is not only certified organic, but it is also fair trade certified (by FloCert in Germany).

When it comes to people’s morning coffee, many of us choose to drink fair-trade coffee. Although cotton bedding is nearly as ubiquitous, fair-trade cotton is not. It should be and we are doing what we can to bring this about.

We have been working with the Chetna Project in India, an organization devoted to growing fair trade and certified organic cotton.

- Begun in 2004, with only 400 farmers as members, Chetna has grown to now over 3,000 members and has a strong presence in four states in India.

The Chetna Project empowers and improves the lives of marginalized peasant farmers who cultivate cotton on a small scale. All Chetna-produced cotton is not only certified as organic, but also fair trade, a distinction that benefits the farmers in a number of ways:

- Fair trade organic cotton sells for about 70% more than conventional cotton

- Child labor is non-existent and workers are paid a fair wage

- Farmers’ organization are democratic and transparent

- Community development is encouraged through health, education and revolving

credit projects.

- Agricultural education and training is on-going

- Groups have access to better markets and can often sell direct to manufacturers,

eliminating middlemen

- Farmers become partners in the business, so they are no longer dependent

on traders

- Fair trade practices strictly prohibit the use of genetically modified organisms

(GMOs), which promoting integrated farm management systems that improve soil

fertility.- Fair-trade cotton is grown without harmful agrochemicals using environmentally

sustainable farming methods that protect people’s health and preserve valuable

ecosystems.

- Although no one is certain of exactly when and where cotton cloth originated, archeologists do know that people were weaving cotton fiber into fabric as long as 4,000 years ago in India and Central and South America. By 1500 A.D, the plant was cultivated throughout the warmer regions of the Americas, Eurasia and Africa.