The textile industry has had a shameful past with its history of manufacturing products that pollute our rivers with deadly toxins, burned down our homes with flammable products, and filling up our landfills with non-biodegradable waste. Fortunately for the safety, health and welfare of all-living species, significant game changing environmentally friendly strategies are replacing these old dangerous methods. This article presents the current eco-trends in textile production and the sustainable solutions created with these textiles for interior window coverings, upholstery and fabric wrapped acoustical panels. Lastly the article will conclude with a presentation on indoor moss walls, an exciting new material used in Biophilic design.

What is a “Sustainable Textile”?

To understand what a sustainable textile is, let’s first look at the definition of sustainable design. According to the American Institute of Architects (AIA), the definition of sustainable design is:

“… a collaborative process that involves thinking ecologically—studying systems, relationships, and interactions—in order to design in ways that removes rather than contribute stress from systems.”

If the goal of sustainable design is to reduce stress to systems; what is the definition of sustainable textiles? To begin with we need to identify the systems that need stress relief. These are the potential areas where textiles and the products produced with them contribute stress to systems. A few areas of these concerns are:

1) Producing textiles that pollute both in its production and as well as in its disposal.

2) Untreated fabrics that can ignite into deadly flames.

3) Poor fiber construction that doesn’t wear or clean well.

4) Flimsy fabrication of products that cannot withstand use and abuse.

Definition of a Sustainable Textile

A sustainable textile is manufactured toxic-free with energy and material coming from recycled sources. The textiles produced are resistant to fire, stain, wear, mildew, pilling and fading. At the end of the finished product’s life cycle, the sustainable textile can be recycled back into other useful products.

Guidelines for Sustainable Textiles

Recycled Polyesters

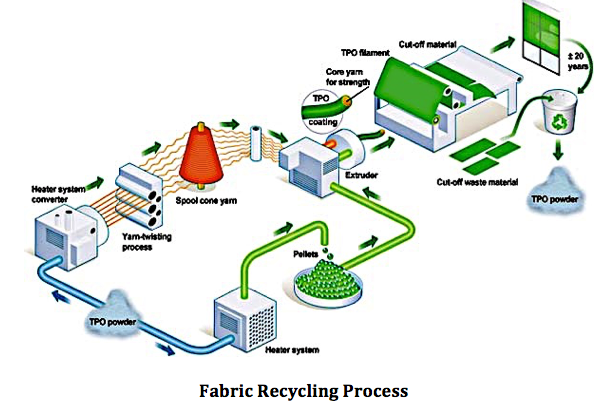

Cradle to Cradle – Fabrics certified as Cradle to Cradle by MBDC (McDonough Braungart Design Chemistry) are able to be recycled back into the manufacturing process and produce new products.

The Repreve Process – Repreve uses PET (clear plastic water bottles) as the raw material. The bottles are sterilized, dried and crushed into small chips. The chips are heated and passed through a spinneret to form yarn and then wound up on spools. The fiber is treated to be suitable for weaving into polyester fabric.

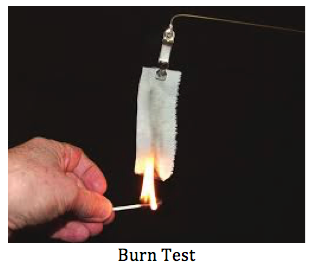

- Fire Rating Guidelines for Upholstery Fabrics

California Bulletin 117 SEC E: Determines the ease of ignition and burning rate when specimen is subjected to a 5/8” open flame for 1 second.

NFPA 260/UFAC: Measure the ability to resists ignition by a smoldering cigarette when the specimen is tested in combination with polyurethane foam cushioning. - Fire Rating Guidelines for Drapery Fabrics

NFPA 701: Measure the ignition resistance of a slightly restrained specimen when exposed to a very severe flame.

- Durability of Textile

Ease of Cleaning – Solution dyed yarns are inherently stain resistant and will never wear off.

Resistant to Pilling – The Martindale Pilling test measures the propensity of a fabric to form pills (bunches of balls of fabric fibers which are held to the surface by one or more fibers). Fabrics comprised of filament yarns are inherently resistant to pilling.

50,000 + Double Rubs – The industry standard for testing the long lasting strength of an upholstery fabric is with the double rub test with a Wyzenbeek machine.

Fade Resistant – Fade resistant fabrics meet or exceed 1500 lightfast hours and will resist fading even when exposed to hot sun or dry temperatures.

Anti-Microbial and Mildew Resistant – Fabrics with silver ion technology have the ability to resist and inhibit the growth of microorganisms as well as suppress the growth of harmful mold, mildew and fungus.

Seam Slippage Resistant – Upholstery fabrics are tested for seam slippage, which is the measurement of the ability of a sewn seam to resist slippage or breakage when subjected to tension. The number of pounds of pressure required to separate the sewn seam determines the rating.

- Solution Dyeing of Fabrics

Most fabrics are conventionally bath-dyed, which means the yarns are dyed after they are produced. Solution dyeing means that color is added to the fibers while they are in a liquid state during the yarn manufacturing process. The color is integrated into the very fiber, which is why the fabric can be cleaned with bleach and still retain the color. Think of the analogy of a carrot and a radish; the color in the carrot is throughout, while the color on the radish lies on the outer surface. The carrot would represent a solution dyed fiber, the radish is the bath-dyed fabric.

Contract Window Fashions

Designing window fashions for contract requires certain details not necessarily an issue in residential design. In Erik Larson’s the book The Devil in the White City, there is a quote by the architect Daniel Burnham where he offers a philosophy on the design of the 1892 Chicago World’s Fair that “function dictate form”.

This is evident when it comes to designing sustainable drapery and window coverings. Where as in residential treatments, function can easily be overlooked in exchange for design. In commercial applications the treatment must function successfully over and over again and be dependable with lots of usage and possibly abuse. Even before form or style is considered, function must be determined. The Architect will identify, in consultation with the client the function requirements of the window coverings by addressing such needs as: light control, privacy issues, stack-backs, mechanisms, mounting and then finally style selections.

Successful Contract Window Fashions

SnapPleat Drapery

The SnapPleat drapery is a simple drape that has no pleats. A fabric tape creates its shape with snaps sewn to the top edge of the drapery panel. When these snaps are attached to the carriers on the rod, this creates the “S” shape design. The weight of the fabric and the function will determine the appropriate fullness. This treatment is one of the best functioning vertical stacking treatments. The SnapPleat drapery can be fabricated with a wide range of fabrics from a lightweight sheer to a drapeable woven. SnapPleat drapery can also be lined with a translucent or blackout lining.

A few of the attributes of the SnapPleat Drapery are:

- Soft flowing appearance

- Panels can be pressed flat

- Easy to remove and install for cleaning

- No Hooks or Pins needed

- Low track profile

- Smaller Stack-back then pleated drapery

- Looks good from front or back.

Roman Shades

Roman Shades are among the best horizontal stacking treatments. The Soft-Fold Roman (pictured on the left) or Flat Roman (pictured on the right) are considered “constructed” due to the fiberglass rods or stays that are inserted at horizontal intervals. The constructed version gives these shades dependable function when they are raised or lowered as they stack into neat folds.

Roman Shades are durable and able to handle rough treatment of fabricated with certain robust features. There is also great range of fabric options, from sheers to wovens. Roman shades can be unlined, tranclucent lined or blackout lined.

Acoustical Solutions

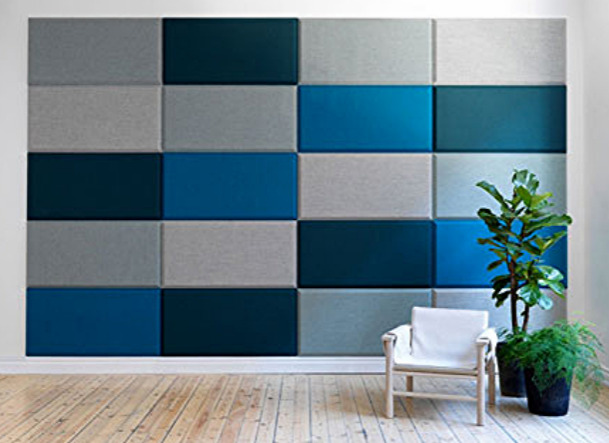

Fabric wrapped acoustical panels are very effective at reducing sound bouncing off hard reflective surfaces. Everyone has experienced being in a public space when you cannot hear the person speaking right next to you. Bars and restaurants used to exploit reflective surfaces by installing tin ceilings to enhance the loud party atmosphere. To dampen this effect, fabric wrapped acoustical panels will absorb sound rather then bounce the sound waves around the room.

When a sound wave strikes a fabric wrapped acoustical panel the sound wave causes the fibers of the substrate to vibrate. This vibration causes tiny amounts of heat, due to the friction, and thus sound absorption is accomplished by way of energy to heat conversion. The more fibrous a material the better for absorption; conversely denser materials are less absorptive. The material thickness also has an impact on the material’s sound absorbing qualities. That is why a 1” thick panel has a Noise Reduction Coefficient (NRC) rating of .85 while a 2” thick panel rates at 1.15.

What is Noise Reduction Coefficient (NRC)?

NRC is the number, which rates the effectiveness of a material at absorbing sound. NRC Ratings can range from 0 (indicating a perfectly reflective material, like glass) to 1 (indicating a perfectly absorptive material).

One way to look at NRC ratings is to see them as a percentage of sound that comes in contact with a sound absorption material and is not reflected back into the room. For example, a NRC of .7 would indicate that the material absorbs 70% of sound waves.

Fabric Wrapped Acoustical Panels

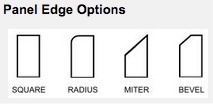

Fabric wrapped acoustical panels come in any size up to 48” wide by 120” high and in 1” or 2” thicknesses. The panels can have a variety of edges, square, radius, mitered or beveled.

The fabrics used for the panels must be tested to make sure it can be glued to the substrate. Also, it is important that the fabric is “acoustically transparent” which means that the sound passes through the fabric with out absorption allowing the substrate to do the work.

Biophilic Design

Over a thousand years ago, the Zen Monks in Japan would plant moss on their walls and in their temple gardens to create a sensation of tranquility. For many moss was an important element that facilitated a communion with nature, a break from the daily routine and a welcoming environment for meditation.

This technique today of incorporating nature into the built environment is called Biophilic Design. Indoor Moss Walls are only a small segment of Biophilic design solutions, which has the proven ability to reduce stress, enhance creativity, provide clarity of thought, improve our well being and expedite healing.

In coming decades, it is projected that over two-thirds of the world’s population will live in cities. With this shift, there is a need for our designs to reconnect people to an experience of nature and now more then ever Biophilic Design is not just a luxury; it’s a necessity for our health and well-being.

A space with a good visual connection with nature feels whole, it grabs one’s attention and can be stimulating or calming. It can convey a sense of time, weather and other living things.

Stress recovery from visual connections with nature have reportedly been realized through lowered blood pressure and heart rate; reduced fatigue, sadness, anger, and aggression; improved mental engagement and attentiveness, attitude and overall happiness. There is also evidence for stress reduction related to both experiencing real nature and seeing images of nature.

Indoor Moss Walls are a great Biophilic Design solution for residential or commercial installations. Moss is not only a beautiful design element they are 100% natural and maintenance free. It does not require sunlight or artificial light, watering or fertilization. The moss lives off the room’s natural levels of humidity. It absorbs odors from the indoor environment and has a NRC rating of .9, which means it absorbs up to 90% of sound.

Indoor Moss walls provide a natural addition to the Biophilic Design solutions toolbox. There is nothing more beautiful and enjoyable then relaxing or working in a space with Indoor Moss Walls.

{{cta(‘f9ed059d-548f-45c5-9026-4ed2b9bc9312′,’justifycenter’)}}